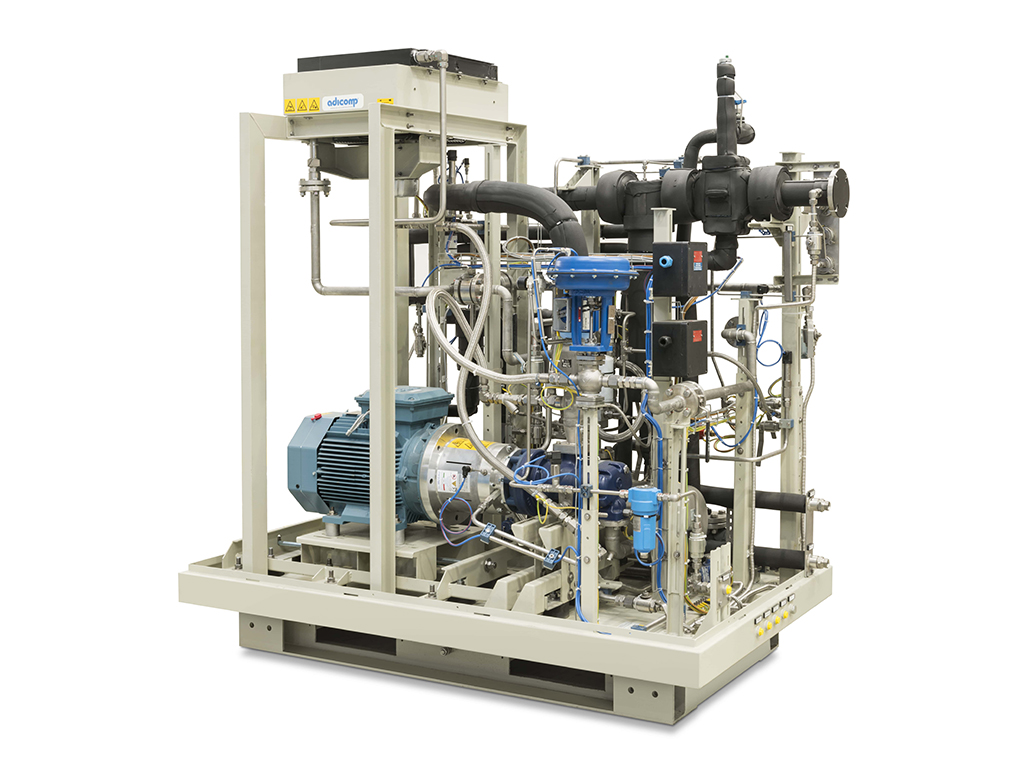

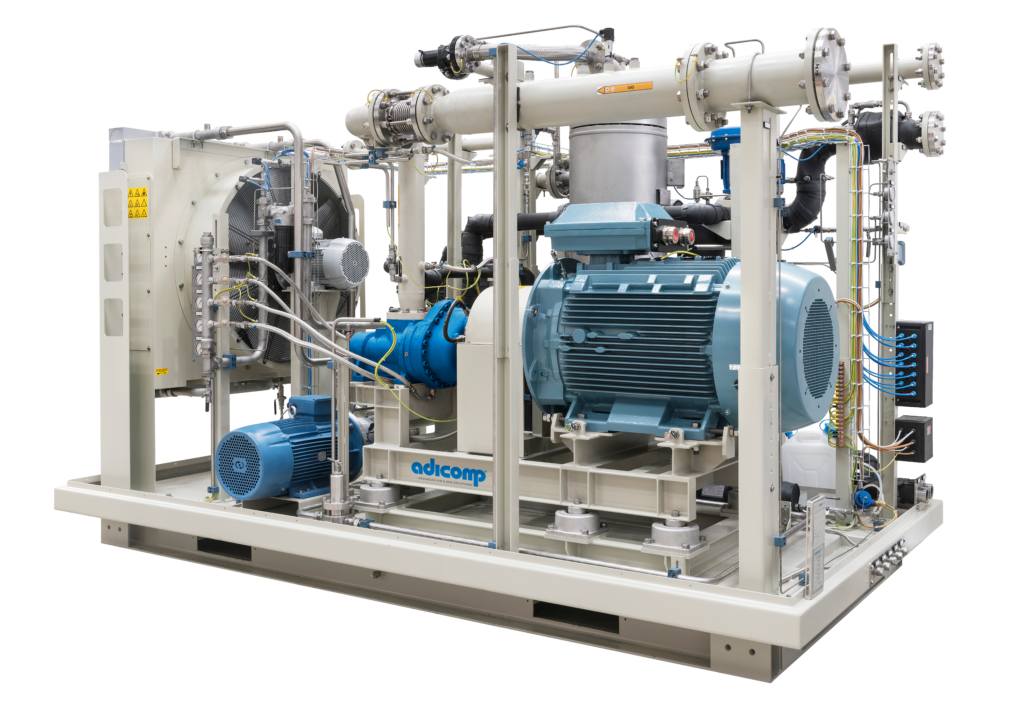

Serie SSG

Estas estaciones de compresión de gas están diseñadas sobre un soporte de fácil traslado, compuesto por un bloque de compresión alternativo y multietapa, basado en la tecnología del pistón. El bloque es accionado con una correa mecánica mediante un motor eléctrico controlado por inversor.

Adicomp se complace en anunciar que ha desarrollado y producido, junto con su empresa matriz Termomeccanica, un bloque de compresión basado en la tecnología del “tornillo” con inyección de aceite de dos etapas, llamado “HTS23” y que, con presiones operativas de entre 15 y 25 bar(g), es más eficiente entre un 10 y un 12 % que un sistema de compresión de una sola etapa.

Estas características se traducen en dos ventajas importantes:

- Un increíble ahorro de energía que se traduce en unos costes de funcionamiento mucho menores (ahorros de 50.000 a 60.000 euros/año para un modelo de 200 kW);

- Cuando se requiere la inyección de biometano en una red que funciona a presiones de 23-24 bar(g), se elimina la necesidad de utilizar un compresor booster, lo que se traduce en grandes ahorros en costes de capital.

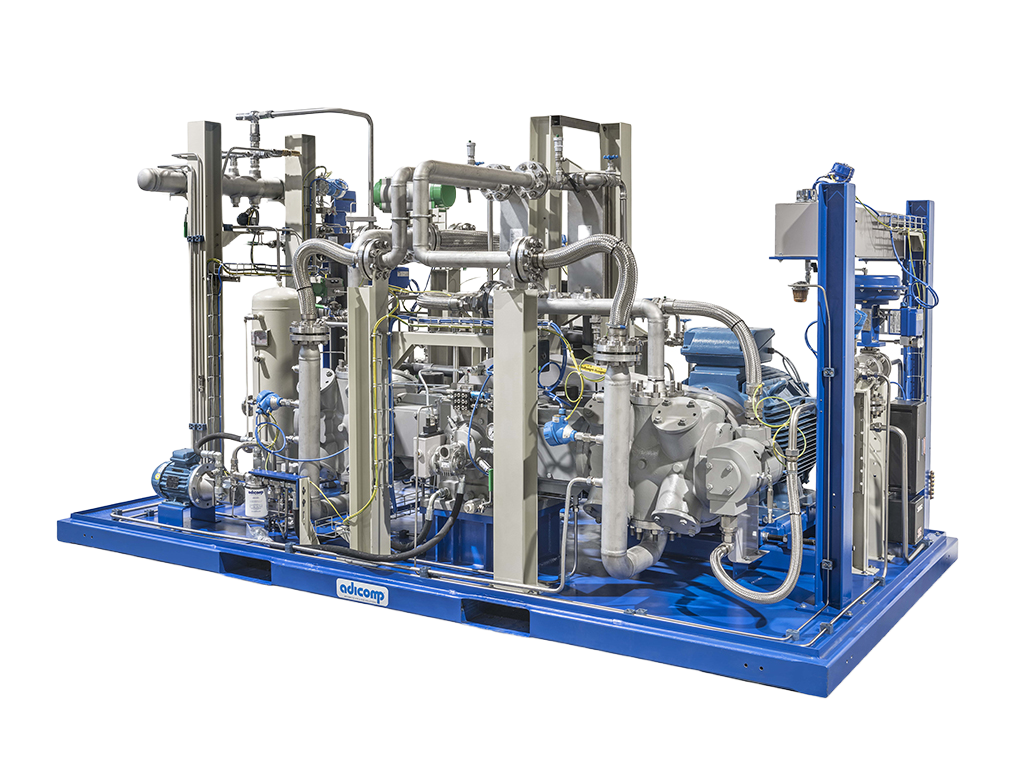

FUNCIONAMIENTO

El gas húmedo es aspirado a través de un filtro de aspiración que cumple también la función de separador del agua y del gas, mediante un sistema automático de desagüé el agua de condensa es eliminada, a continuación el gas pasa a través de una válvula de aspiración. Todos los componentes en contacto con el gas están fabricados en acero inoxidable o debidamente protegidos, debido a la posible presencia de H2S, CO2 y otros contaminantes agresivos presentes en el gas. Durante el proceso de compresión del gas, el aceite se inyecta en el interior de la cámara del tornillo rotativo, para realizar tres funciones principales: lubricación, sellado y absorción de calor. Trabajando en un circuito cerrado con un separador de gas/aceite, el aceite se presuriza para fluir a través de un enfriador de aceite y, a continuación, se filtra antes de ser inyectado de nuevo en la cámara de compresión del tornillo. El gas fluye a través de la válvula de mínima presión/sin retorno, si es necesario, el gas puede someterse a diversos tratamientos para eliminar contaminantes mediante filtros e intercambiadores..