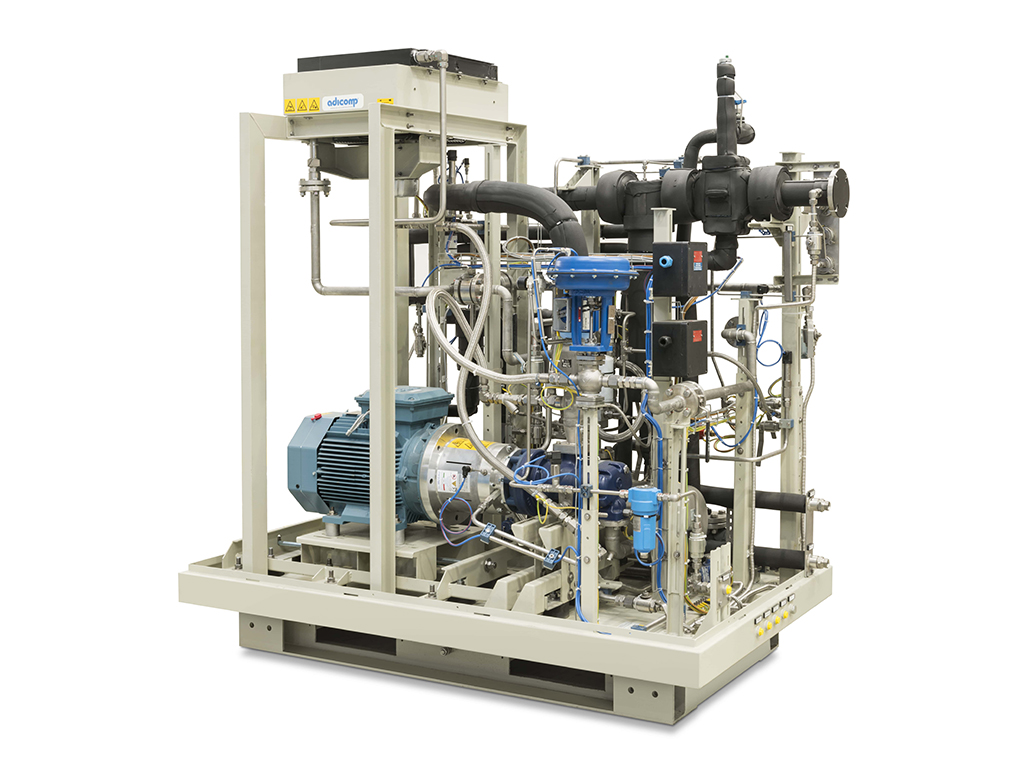

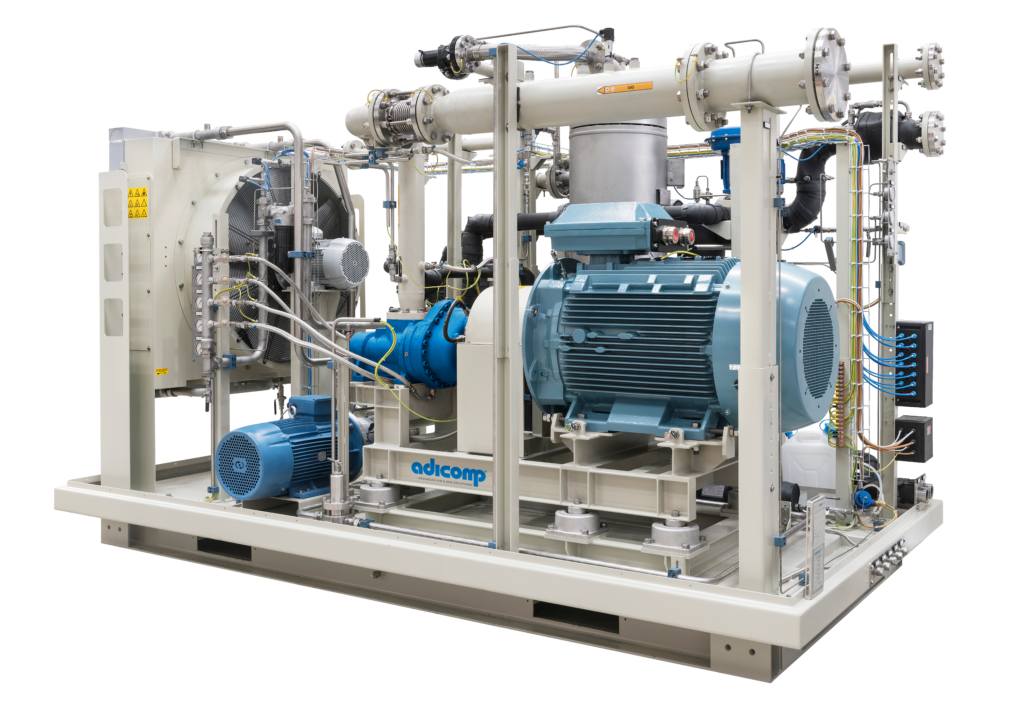

SSG series

These wet or dry gas compression and treatment stations are designed into an easy handling skid composed of a two stage oil-injected rotary gas screw block, directly coupled to an electric motor through a flexible coupling inverter controlled.

Adicomp is pleased to announce that it has developed and produced, together with its parent company Termomeccanica, a two-stage oil-injected screw compressor package that utilises the HTS-23 screw block and which, when operating between 217 and 363 psi(g) discharge pressure, has 10-12% higher efficiency than the equivalent single-stage model.

These features result in two important advantages:

- An incredible energy saving resulting on much less running costs (savings of 50,000-60,000 dollars/year for a 270 Hp model);

- When biomethane injection into a grid operating at pressures of 333-348 psi(g) is required, there is no need to install a final gas booster, resulting in large savings in capital costs.

HOW IT WORKS

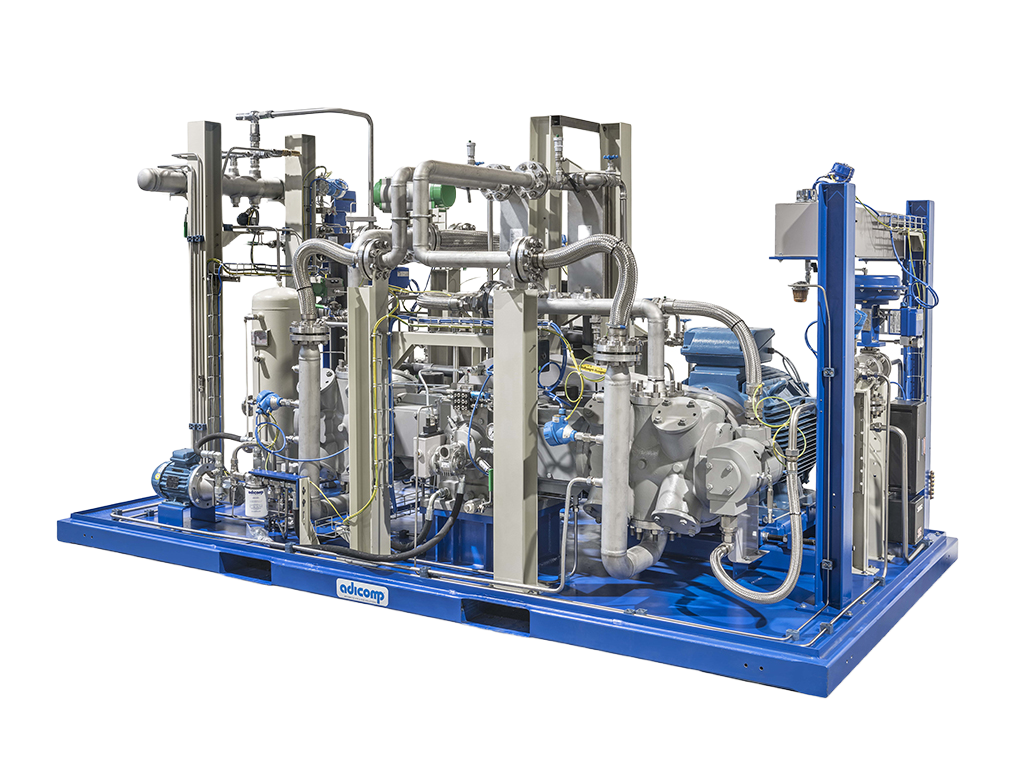

The wet gas is sucked through a suction filter acting also as a water separator with automatic condensate drain system, then the gas passes through a suction valve.

All the components in contact with the gas are made in stainless steel or duly protected, due to the presence of H2S, CO2 and other aggressive contaminants into the gas.

During the gas compression process, the oil is injected inside the two stage rotary screw chamber to perform three main functions: lubrication, sealing and heat absorption, cooler and it is treated before leaving the package.

Working in a close circuit with a gas/oil receiver, oil is pressurized to flow trough an oil cooler, then filtered before being injected again into the screw compression chamber. The gas flows through the minimum pressure /no-return valve into a cooler and it is treated before leaving the package.